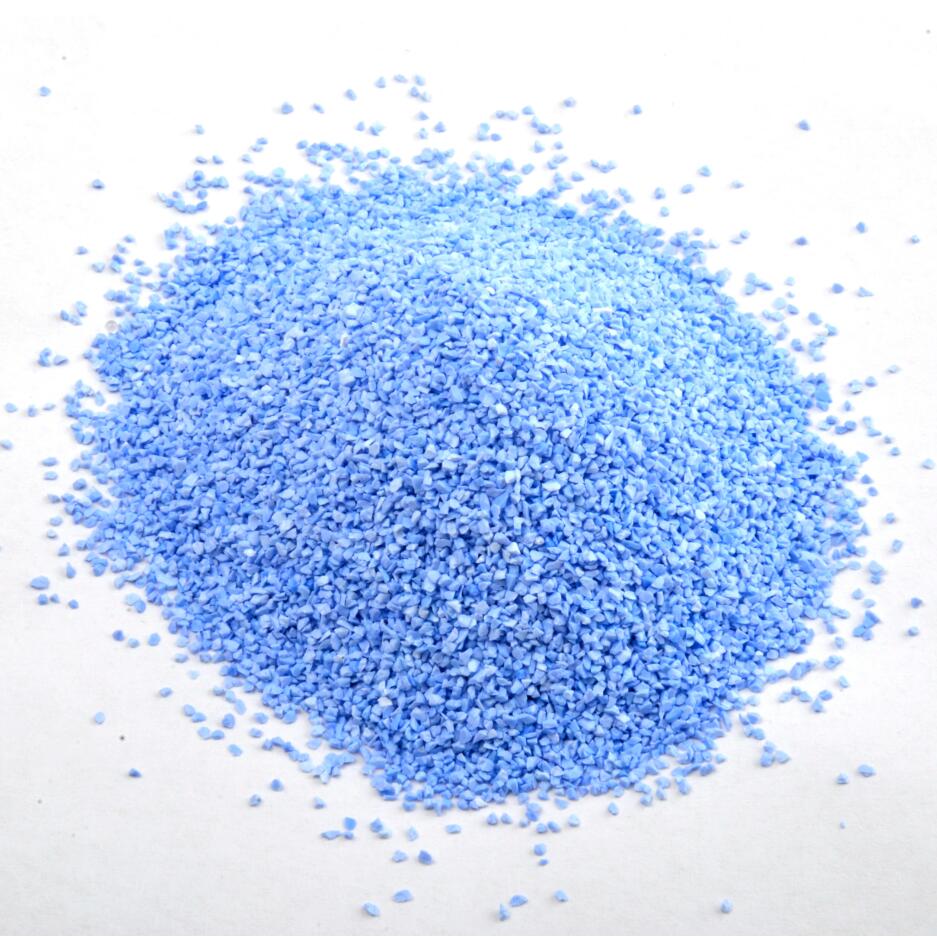

Why is SG abrasives blue?

The main reason is due to its production process and material properties. SG abrasives is sintered by a special seeding gel system.

The silicate target contains highly active silicon elements. It will form a stable silicon dioxide layer under high temperature. The color of this silicon dioxide film is mainly blue, which greatly improves the wear performance and wear resistance of SG ceramic abrasives.

In addition, after heat treatment, the color of the silicon dioxide layer will change to a certain extent, forming a fine structure, which makes the surface of the abrasives smoother and improves its wear resistance. This process makes the abrasive contain thousands of tiny crystals, which gives SG ceramic abrasives a unique blue appearance.

The blue appearance is not only beautiful, but more importantly, its performance is superior. It has an extremely high wear ratio and strong conformality, and can remain sharp for a long time under high load, reducing downtime and improving production efficiency.

In addition, the self-sharpening property enables it to continuously expose new sharp cutting edges during the grinding process, reducing the number of corrections, and further improving its use efficiency.

Compared with ordinary aluminum oxide abrasives, SG abrasives perform well on difficult-to-grind materials such as aviation and aerospace alloys and forged steels, enabling efficient cutting and reducing labor costs. These characteristics give it significant advantages in industrial applications, especially in processing environments that require high efficiency and long life.