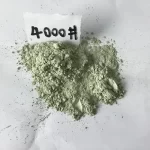

Why does white fused alumina exit black spot?

There’re black spots in white fused alumina, may be because the impurities it carries are not removed clean. Rust is a more common magazine, because the white fused alumina raw material itself exists iron oxide, if not removed clean, there will be black spots. In addition, in the production process, because the mechanical rust will also accidentally incorporated rust, eventually leading to the color of white corundum is not pure.

From the production point of view, if the smelting time is insufficient, or the smelting process is immature, it will lead to low purity of white fused alumina, high impurity content, and small black spots will be seen in the color.

In general, whether the color of white corundum is pure is one of the standards for detecting the quality of white fused alumina. If the quality of white fused alumina is not up to the standard, it will have a great impact on its performance, the most obvious reflected in the hardness and grinding force. Therefore, manufacturers must be strict in production and pay more attention.