What is the use of zirconium corundum?

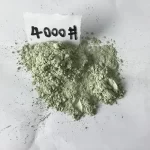

Zirconia corundum is made of alumina and zirconium oxide, and is smelted at a high temperature of more than 2000℃ in an electric arc furnace. Its main mineral phase is the eutectic formed by a-Al2O3 and Al2O3-ZrO2, the secondary crystal phase is baddeleyite, and there is also a small amount of glass phase. According to the content of ZrO2, zirconium corundum is divided into 25 zirconium corundum (ZrO2 25%) and 40 zirconium corundum (ZrO2 40%).

The main uses of zirconium corundum include the following aspects:

Abrasive application:

Zirconium corundum, as a high-grade abrasive, has the characteristics of good resistance to melt erosion, high hardness and strong wear resistance. It is suitable for the manufacture of high-performance heavy-duty grinding wheels, sanding belts, cutting discs, rough grinding, etc. It has a good grinding effect on steel parts, cast iron parts, heat-resistant steel and various alloy materials.

Refractory material:

Zirconium corundum is an ideal material for making high-performance sliding nozzles and immersed nozzles. It is also used to make high-grade refractory materials such as zirconium corundum bricks for glass melting furnaces. It is widely used in metallurgy, steelmaking, glass, ceramics, cement and other industries, such as sandblasting, polishing, etching, etc. of metal and non-metal surfaces.

Zirconia corundum can also be used to make high-end building materials, such as high-end building materials and zirconium corundum bricks for glass melting furnaces. Other applications: Zirconia corundum micropowder is mainly used to make grinding paste, polishing wax, sandpaper, etc., suitable for various precision processing and surface treatment.