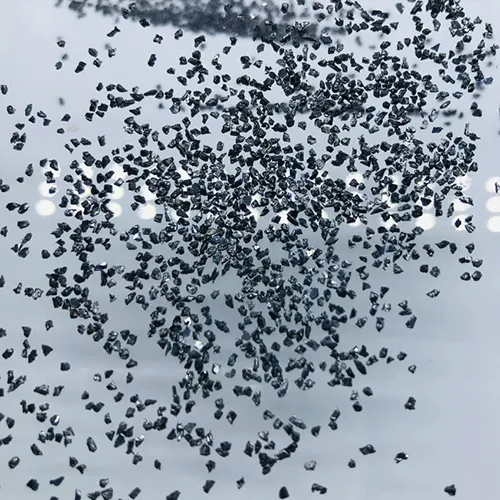

What are the advantages of adding black silicon carbide to cables?

The main reason for adding black silicon carbide powder to cables during production is to enhance the performance of the cables by utilizing its conductivity and physical properties. Black sic has excellent conductivity, which allows it to be used as a conductive material in cables to help improve the conductivity of cables. In addition, the physical properties of black silicon carbide, such as high hardness, good wear resistance and thermal stability, enable it to provide better mechanical protection and high temperature resistance in cables.

Specifically, the application of black sic in cables includes the following aspects:

Conductivity: The conductive properties of black silicon carbide enable it to provide better current conduction in cables, reduce resistance, and thus improve the transmission efficiency of cables.

Wear resistance: The high hardness of black sic enables it to provide better wear protection in cables and extend the service life of cables.

High temperature resistance: Black sic has good thermal stability and high temperature resistance, and can maintain stable performance in high temperature environments, making it suitable for cables that require high temperature environments.

Physical protection: Its high strength and hardness can provide physical protection for the internal structure of the cable to prevent external damage from affecting the performance of the cable. Through these characteristics, the application of black sic in cables can significantly improve the overall performance and service life of the cables.