Elastic grinding blocks are made of white fused alumina?

Production elastic abrasive blocks are not limited to white fused alumina, but also can be used with other abrasives, such as: brown fused alumina, black silicon caebide, green silicon carbide, diamond, etc.

The elastic module is the sponge grinding block, which is widely used in the surface treatment of metal, wood, paint, glass, stones, cars, plastics, leather, etc.

It is mainly used for the polishing and cleaning of the metal surface oxidation layer, removing, rust removal, surface polishing, and radiation patterns. At the same time, it is also an indispensable tool for removing glue and cleaning oxide layer in the solar industry! Restoration and cleaning on the surface of the products such as instruments.

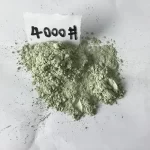

Elastic grinding blocks are made of artificial abrasives (such as: black carbide, silicon, green silicon, Bai Gangyu, browning jade) and polymer resin processed by special processes. Black carbide, green silicon, white gangsu, brown gang jade can be used for the production of elastic grinders. The difference is that customer demand is different, the effects are different, and the costs are different. Different abrasive products can be used. What’s more, use diamond to produce diamond grinding blocks on the surface of the resin. The hardness is higher, the polishing effect is better, and the life span is longer. Of course, the cost is higher. Therefore, customers should buy elastic grinders of different raw materials according to their needs.