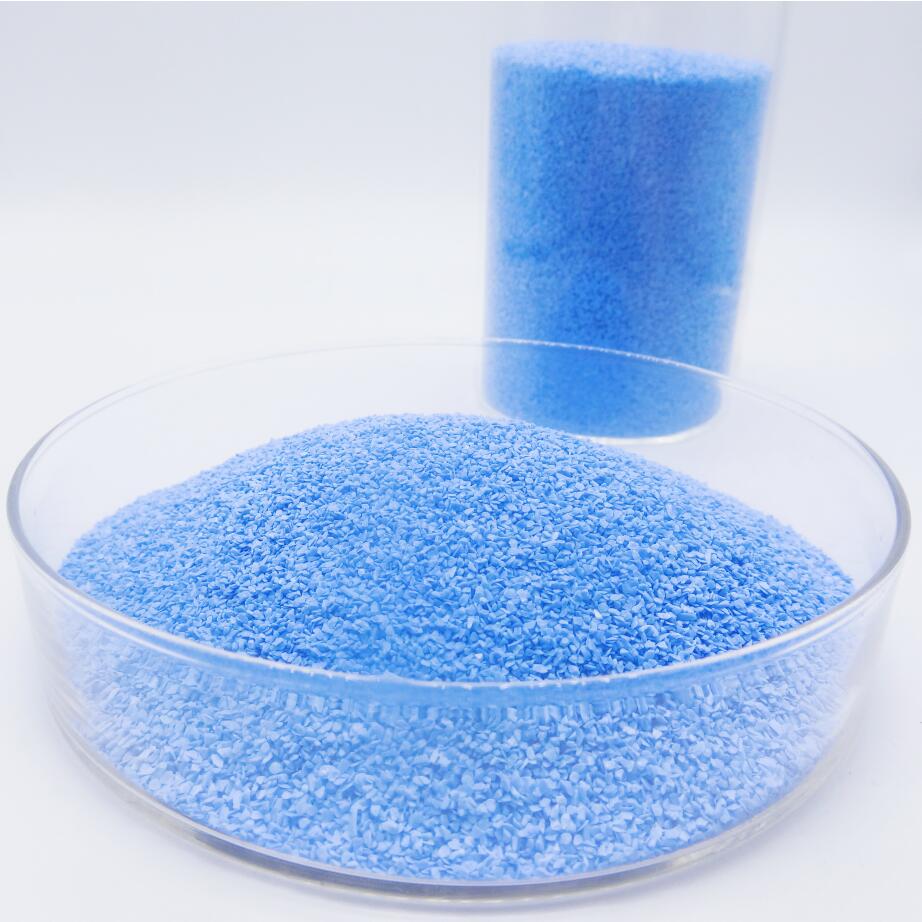

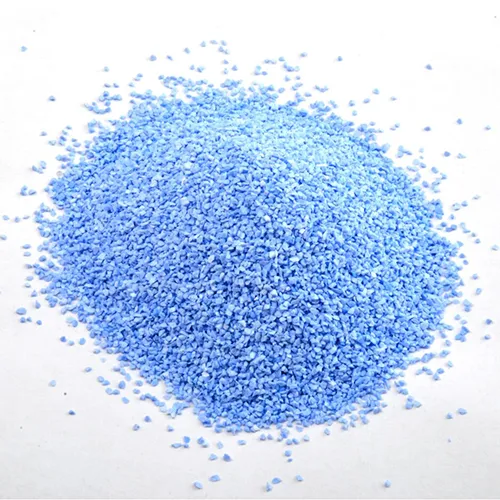

Sintered SG abrasives by sol-gel method

Sintered SG abrasives is prepared by the sol-gel method, using micron-grade aluminum oxide, adding a series of high-tech formulas to complete the sol-gel process, and then undergoing a series of supporting processes to make abrasive particles. The raw material technical conditions and process requirements are strict. By adding modifiers with different properties and controlling the gel conditions, microcrystals with different structures can be obtained, and the microcrystals are arranged in an orderly manner.

Available sizes for ceramic SG abrasives:

| Standard | Grit size | Powder |

| Fepa F sand | F16#-220# | F230#-1500# |

| Fepa P sand | P20#-220# | P240#-2500# |

| JIS | JIS240#-4000# |

Physical and chemical indexes for ceramic SG abrasives:

|

Physical index |

||||

|

colour |

microlitic structure |

Vickers hardness |

True density |

thermal resistance |

|

bule |

crystallite dimension 50-500nm Lamellar accumulation |

1850-2100khf/mm2 |

≥3.85g/cm3 |

1300℃ |

|

Chemcial index |

||||

|

Al2O3 |

La2O3 |

MgO |

Y2O3 |

Others |

|

90-100% |

1-3% |

1-3% |

1-3% |

0-0.5% |

Usage for ceramic SG abrasives:

Coated abrasives, consolidated abrasives, superhard materials, etc

Package for ceramic SG abrasives:

Ceramic sintered SG abrasives has the following characteristics:

1. High hardness: SG ceramic abrasive has high hardness and can be used to grind superhard materials such as diamond, cubic boron nitride, etc., showing advantages that general corundum, silicon carbide and other abrasives cannot match.

2. Good self-sharpening: Due to the refined crystal structure, SG ceramic abrasive can fall off regularly in layers during the grinding process, always maintaining the sharpness of the entire abrasive. This self-sharpening not only speeds up the cutting speed and shortens the time for processing the workpiece, but also ensures good processing results.

3. High sharpness: SG ceramic abrasive can quickly cut into the workpiece surface during the grinding process, improving grinding efficiency. Good toughness: SG ceramic abrasive is not only hard, but also has good toughness. It is not easy to break during the grinding process and can maintain a long service life.

4. High grinding efficiency: Due to the high hardness, good sharpness and good self-sharpening properties of SG ceramic abrasives, their grinding efficiency is much higher than that of traditional abrasives, which can not only improve production efficiency but also reduce production costs.

SG ceramic abrasives have a wide range of applications and are suitable for grinding a variety of materials such as aerospace alloys, hardened workpieces, tool steel, hard cast iron, bearings, heat-resistant alloys, and cutting tools. In addition, SG ceramic abrasives are also suitable for grinding materials such as stainless steel, hardened steel, tool steel, hard chrome steel, hard cast iron, high chromium alloys, titanium alloys, and nickel-based alloys.