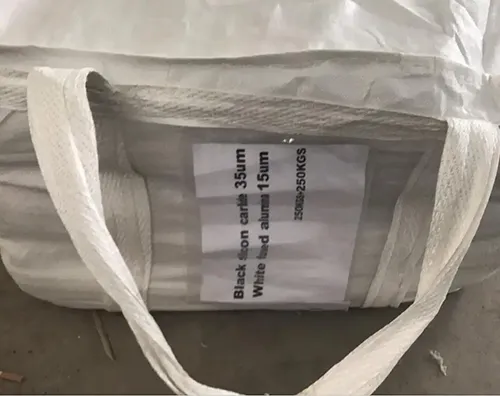

Product Description

Black silicon carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke as its main raw materials. Its hardness is between fused alumina and synthetic diamond. Mechanical intensity of it is higher than fused alumina. It is brittle and sharp and has electrical and heat conductivity in some degree. The abrasives made of it are suitable for working on cast iron, non-ferrous metal, rock, leather, rubber, etc. It is also broadly used as refractory material and metallurgical additive.

Used for abrasives,blasting,grinding

| properties

Type |

Grains | ||

| 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | |||

| Guarantee Value | Typical Value | ||

| Chemical

Composition |

SIC | ≥98 | 98.5 |

| F.C | ≤0.2 | 0.1 | |

| Fe2O3 | ≤0.2 | 0.15 | |

| H2O3 | ≤1 | 0.3 | |

Used for abrasives ,lapping,Polishing

| Properties

Type |

Micropowder | |||

| W | W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 | |||

| FEPA | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 | |||

| JIS | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 8000# | |||

|

Guarantee Value |

Typical Value |

|||

| Chemical

Composition |

SIC | ≥97 |

97.5 |

|

| F.C | ≤0.3 |

0.2 |

||

| Fe2O3 | ≤0.2 |

0.15 |

||

| H2O3 | ≤1 |

0.3 |

||